What is risk analysis?

The vast majority of international standards are based on the concept of risk. Thus, it is pretty interesting for the manufacturer to conduct a risk analysis at different times of design and production to identify the main offenders, weaknesses, and security risks and know how to prepare a document that manages and classifies these risks, establishing the most tangible and cost-effective way to implement actions to mitigate them.

A risk can be translated as the joint action of the frequency of occurrence with the effect caused. Risk analysis can be quantitative or qualitative.

Mathematically, it can be said that the risk is the level of its occurrence multiplied by the level of its severity, that is,

R = O x S

Where:

R is the quantified risk,

O is the frequency with which it occurs, and

S is its severity

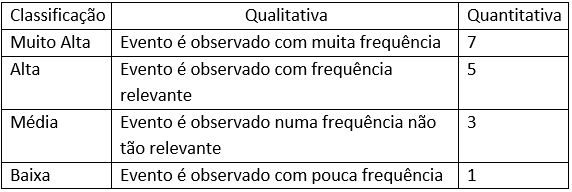

As an example, the frequency of occurrence can be classified with a qualitative and a quantitative description:

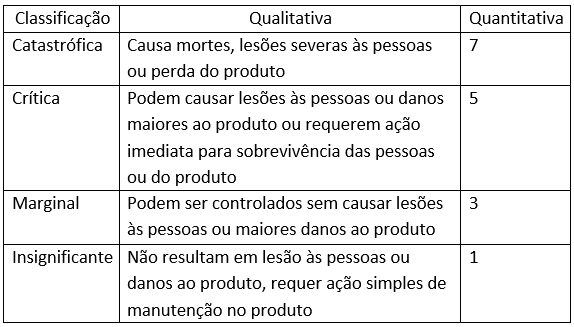

Likewise, one can classify, for example, the severity of the occurrence:

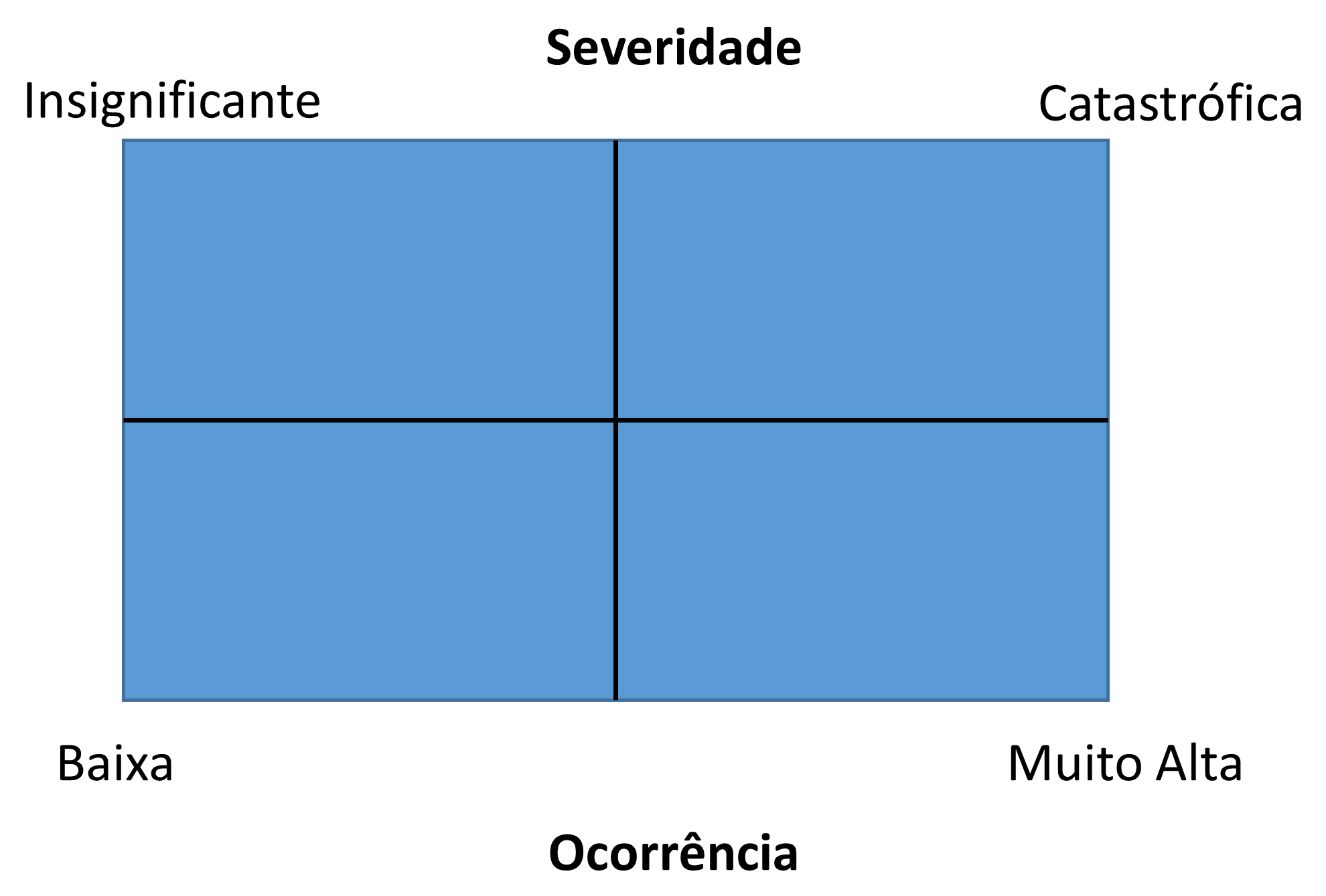

In a graphic view, it can be seen that the most significant risk is located in the upper right quadrant:

In the examples above, the highest risk is quantified as 49, classified with a very high frequency of occurrence and catastrophic severity.

That is, the greater the product between frequency of occurrence and severity, the greater the risk.