Quality in product design

A product design must be conceived and developed using techniques that ensure quality and reliability throughout the product’s life cycle.

In the 1960s, quality control was remedial. Subsequently, it evolved with the improvement of inspection techniques, statistical methods, and development tests related to safety, performance, and reliability, and still working with the concept of total quality – suitability for use and quality in the project.

Factors affecting quality are materials, technology, machines, methods, people, operators, and management (according to Ishikawa and Feigenbaum).

In a production cycle, attention should be paid to the following approaches below, not limited to these:

- Lack of coordination of the teams that participate in the different stages of the production cycle;

- Undefined responsibilities for control actions;

- Non-traceable flow of information;

- Incomplete survey of customer expectations and requirements;

- Lack of after-sales support;

- Lack of monitoring of skills of people responsible for functions that affect quality.

The planning process for a new product should have a well-defined objective, considering the following:

The product lifecycle can be presented as follows:

- Phase 1 – Conceptual and Planning

- Phase 2 – Design and Development

- Phase 3 – Production

- Phase 4 – Operation and Maintenance (disposal)

Techniques used in the control of new projects:

- Market analysis and product planning;

- Statistical analysis of new projects;

- Failure analysis (mode, effect, and criticality);

- Human factors analyses;

Studies related to the improvement that will be carried out in each characteristic, considering their effects on the others (“tradeoff studies”). For example, reliability X complexity X weight X cost X safety X performance X consequence of failures X manufacturing possibility X inspection possibility X maintenance possibility, etc.;

Analysis of the performance of suppliers of components, parts, and spares;

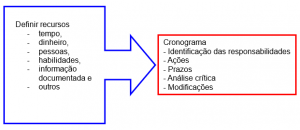

Planning, which means previously analyzing the sequence of actions and following a proposed work plan to achieve a specific objective.

Well-executed quality planning defines a roadmap for the company to deliver new or redesigned products, without defects, on time, and at a pre-established cost. This planning must consider the organizational structure, critical analysis of the project, performance tests, reliability tests, safety tests, tooling potential studies, tolerance analysis, and product certification.

NCC has market recognition in product certification and competent professionals to provide full support and assess the quality of your product design.

The material is subject to amendment(s) in case of change in the ordinance(s). Published: 12/13/2022